Effectiveness and Scalability: Quad-head machines are highly successful and adaptable, producing them suited to intricate PCBs and large creation runs.

Lowered Manufacturing Time: They will significantly reduce the time needed to assemble a lot of PCBs, building them Value-powerful in mass manufacturing eventualities.

Each style of placement machine has its individual structure for courses but they all comprise the identical facts which include - aspect quantities, circuit board reference, rotation, package deal data and X/Y situation.

These units keep and provide factors towards the machine for placement. They contain tape feeders, tray feeders, and tube feeders, making it possible for for any seamless circulation of factors.

Floor mount components are placed alongside the front (and infrequently back again) faces on the machine. Most factors are equipped on paper or plastic tape, in tape reels which might be loaded onto feeders mounted for the machine. Bigger integrated circuits (ICs) are sometimes equipped and organized in trays which might be stacked in a compartment.

Their power to posture factors correctly is significant for that trustworthiness and functionality of the final merchandise.

Whether you are searching for a totally automated pick and place machine or one among our specialty solutions, Manncorp can provide a substantial-high quality machine for the software and life time machines aid from our in-dwelling technological workers.

Data Sheet LE40 benchtop design of pick and place machines features technologically Superior, low priced remedies for small to medium quantity SMT placement apps.

The machine is programmed to improve the pick and placement for each PCB, being aware of what components are demanded for that PCB, in which the parts can be found on the placement machine and where the bare PCB is situated in the working space.

The higher diploma of precision don't just boosts the quality of the ultimate product but will also makes certain compliance with stringent business expectations. By reducing problems, companies can achieve higher initially-move yields and boost overall output effectiveness.

Scalability: Pick and place machines is usually scaled to match modifying manufacturing wants, building them adaptable for the two small and enormous-scale production functions. This scalability makes certain that clients can modify their output potential as need fluctuates.

The person interface of JUKI RS-1R pick & place machine is intuitive and user-helpful, making it effortless for operators to learn and use, lowering teaching expenses and generating the Procedure clear-cut.

Fiducial Marks - Fiducial marks are simply just styles within the keep track of layer of the PCB which have been positioned wherever they cannot be puzzled with other areas of the board structure. – Illustrations is automatic pick and place machine often witnessed underneath:-

Ingredient dimensions and place – Extremely populated types might have small elements positioned close to larger sized parts which ought to be taken under consideration when making the placement application.

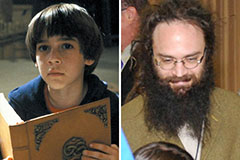

Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now!